Site Blog

Ligne de machines de fabrication de production de cellules cylindriques automatiques

fabrication et équipement de laboratoire de batterie de Li-ion 18650

Organigramme de la pile bouton au lithium-ion et liste des machines

fabrication et équipement de laboratoire de batterie de poche de li-ion

dec 2016 usa client acceptation d'usine de l'empileuse automatique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produits chauds

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

Battery materials are the essential components that enable the storage and release of electrical energy in batteries. These materials determine the performance, efficiency, safety, and lifespan of a battery. As demand for sustainable energy solutions grows, advancements in battery materials play a critical role in meeting the needs of electric vehicles (EVs), renewable energy systems, consumer electronics, and more.

In this article, we will explore the key materials used in batteries, their roles, advantages, challenges, and innovations driving the future of energy storage.

●Key Components of Battery Materials

A typical battery consists of four main components:

1. Anode (Negative Electrode)

The anode stores and releases lithium ions during charging and discharging.

Common materials: Graphite (for Liion batteries), silicon, lithium metal.

2. Cathode (Positive Electrode)

The cathode receives lithium ions from the anode during discharge.

Common materials: Lithium cobalt oxide (LCO), lithium iron phosphate (LFP), nickel manganese cobalt oxide (NMC), nickel cobalt aluminum oxide (NCA).

3. Electrolyte

The electrolyte facilitates ion movement between the anode and cathode.

Common materials: Liquid electrolytes (e.g., lithium salts dissolved in organic solvents), solidstate electrolytes (e.g., ceramics, polymers).

4. Separator

The separator prevents direct contact between the anode and cathode while allowing ion flow.

Common materials: Polymeric membranes, ceramiccoated separators.

●Types of Battery Materials

1. Active Materials

Anode Materials:

Graphite: Widely used due to its high capacity, stability, and low cost. However, it has limitations in fast charging.

Silicon: Offers higher energy density but suffers from volume expansion during cycling, leading to degradation.

Lithium Metal: Promising for nextgeneration batteries but faces challenges with dendrite formation and safety.

Cathode Materials:

Lithium Cobalt Oxide (LCO): High energy density but expensive and less stable at high temperatures.

Lithium Iron Phosphate (LFP): Safe, stable, and longlasting but lower energy density compared to LCO.

Nickel Manganese Cobalt Oxide (NMC): Balances energy density, cost, and stability; widely used in EVs.

Nickel Cobalt Aluminum Oxide (NCA): High energy density but requires careful thermal management.

2. Electrolyte Materials

Liquid Electrolytes:

Composed of lithium salts (e.g., LiPF6) dissolved in organic solvents. While effective, they pose risks of leakage and flammability.

SolidState Electrolytes:

Ceramics (e.g., LLZO, LGP): High ionic conductivity and improved safety but challenging to manufacture.

Polymers: Lightweight and flexible but often limited by lower conductivity.

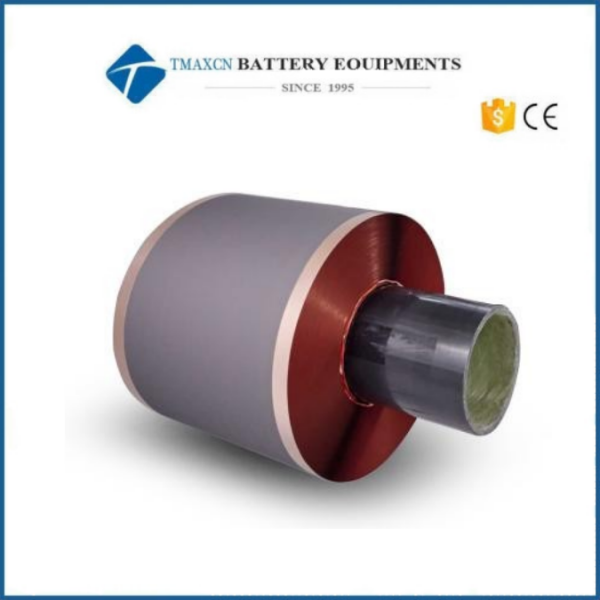

3. Current Collectors

Thin conductive foils (e.g., copper for anodes, aluminum for cathodes) that collect and transfer current within the battery.

4. Binders and Additives

Binders (e.g., PVDF, CMC/SBR) hold active materials together and adhere them to current collectors.

Conductive additives (e.g., carbon black, graphene) enhance electron transport.

●Advantages of Advanced Battery Materials

1. Higher Energy Density

Enables longer runtimes and greater range in applications like EVs.

2. Improved Safety

Solidstate electrolytes and advanced separators reduce the risk of thermal runaway.

3. Faster Charging

Innovations in anode materials (e.g., silicongraphite composites) and electrolytes enable quicker charge cycles.

4. Longer Lifespan

Enhanced stability of cathode materials and reduced degradation mechanisms extend battery life.

5. CostEffectiveness

Use of abundant materials (e.g., iron, phosphate) lowers production costs.

1. Material Availability

Limited supplies of critical elements like lithium, cobalt, and nickel threaten scalability.

2. Environmental Impact

Mining and processing of raw materials contribute to environmental degradation.

3. Safety Concerns

Flammable liquid electrolytes and dendrite growth in lithiummetal batteries pose risks.

4. Degradation Mechanisms

Side reactions, electrode swelling, and electrolyte decomposition reduce battery performance over time.

5. Recycling Challenges

Efficient recovery of valuable materials from spent batteries remains a technical and economic hurdle.

●Innovations in Battery Materials

To address these challenges and enhance performance, researchers and manufacturers are developing cuttingedge battery materials:

1. NextGeneration Anodes

Siliconcarbon composites for improved energy density and cycle life.

Lithiummetal anodes with protective coatings to prevent dendrite formation.

2. Advanced Cathodes

Highnickel NMC formulations for higher energy density.

Lowcobalt or cobaltfree cathodes to reduce costs and environmental impact.

3. SolidState Electrolytes

Development of sulfidebased electrolytes with superior ionic conductivity and flexibility.

4. Sustainable Materials

Use of recycled materials and abundant elements like sodium, magnesium, and zinc.

5. Smart Materials

Incorporation of sensors and selfhealing materials for realtime monitoring and enhanced durability.

●Applications of Battery Materials

Battery materials are used across a wide range of industries and applications:

1. Electric Vehicles (EVs)

Highperformance batteries with long ranges and fast charging capabilities.

2. Renewable Energy Systems

Gridscale storage solutions for solar and wind power.

3. Consumer Electronics

Compact and efficient batteries for smartphones, laptops, and wearables.

4. Medical Devices

Reliable and safe batteries for implantable devices and diagnostic equipment.

5. Industrial Applications

Backup power systems, telecommunications, and heavyduty machinery.

●The Future of Battery Materials

As the global transition to clean energy accelerates, the development of advanced battery materials will be pivotal. Key trends shaping the future include:

1. Increased Efficiency

Higher energy densities and faster charging times through innovative materials.

2. Focus on Sustainability

Greater emphasis on recyclability, reduced reliance on scarce resources, and ecofriendly manufacturing processes.

3. Integration with Emerging Technologies

Combining battery materials with AI, IoT, and nanotechnology for smarter and more efficient energy storage.

4. Global Standards Compliance

Ensuring compatibility with evolving international regulations for battery materials.

5. Expansion into New Markets

Adapting battery materials for emerging fields like aerospace, marine, and quantum computing.

●Conclusion

Battery materials are at the heart of modern energy storage systems, driving innovation and enabling a sustainable future. Their continuous evolution is crucial for addressing global energy challenges and reducing our carbon footprint.

What excites you most about the advancements in battery materials? Share your thoughts below! Together, let’s explore how these groundbreaking materials can shape the future of energy storage and sustainability.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com