Site Blog

Ligne de machines de fabrication de production de cellules cylindriques automatiques

fabrication et équipement de laboratoire de batterie de Li-ion 18650

Organigramme de la pile bouton au lithium-ion et liste des machines

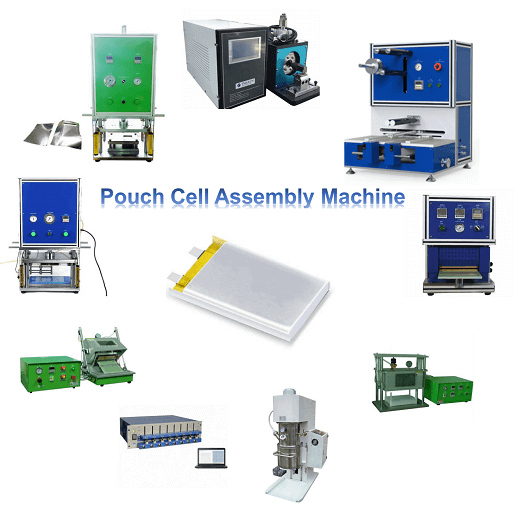

fabrication et équipement de laboratoire de batterie de poche de li-ion

dec 2016 usa client acceptation d'usine de l'empileuse automatique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produits chauds

1. Initial Exploration and Research Phase:

In the early stages of Car Battery assembly Line development, the focus was on laboratory-scale production for basic research and exploration of new battery technologies.

Research Phase: Scientists conducted fundamental research on battery raw materials, including electrode materials, electrolytes, and separators, aiming to discover new materials and enhance battery performance.

Small-scale Experiments: The lab production line was utilized for the small-scale manufacturing of batteries to validate the feasibility of new materials. This involved battery design, assembly, and initial testing.

2. Optimization of Battery Technology and Small Batch Production:

As a deeper understanding of battery technology emerged, the lab production line transitioned from primarily research-focused to optimizing technology and small-batch production.

Optimization of Battery Design: The lithium Battery lab production line was employed to test batteries with different design parameters to improve energy density, cycle life, and safety.

Small Batch Production: The lab gradually began small-scale production for batteries used in practical tests. This small-scale production helped validate battery performance and stability.

3. Advancements in Production Processes and Automation:

To meet the growing demands of the electric vehicle market, Pouch cell Battery Lab Line increasingly focused on production processes and automation.

Optimization of Production Processes: By refining manufacturing processes, the lab production line aimed to enhance battery production efficiency, covering aspects such as raw material management, battery assembly, testing, and quality control.

Increased Automation: Advanced automation equipment and robotics were introduced to reduce manual operations, improving production efficiency and consistency.

4. Large-scale Production and Market Application:

With the maturation of lab production line technology, production scale gradually increased to meet the demands of the electric vehicle market.

Large-scale Production: The lab production line evolved into a large-scale production line to address the growing market demand. The increased scale of production contributed to lowering battery costs.

Market Application: Successful Car Battery Lab Lines became leaders in battery technology, and their produced batteries found widespread application in electric vehicles and energy storage systems.

5. Continuous Innovation and Sustainable Development:

Currently, Car Battery Lab Lines are in a phase of continuous innovation and sustainable development.

Introduction of New Technologies: The lab production lines are introducing new battery technologies, such as solid-state batteries and high-energy-density batteries, to further enhance battery performance.

Consideration of Sustainability: There is an emphasis on the sustainability of the production process, including the renewable nature of raw materials and the energy efficiency of the production process.

Smart Manufacturing: Utilizing advanced information technology, intelligent manufacturing is being implemented in battery production, including data analytics, remote monitoring, and predictive maintenance.

ru

ru English

English

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com