Site Blog

Ligne de machines de fabrication de production de cellules cylindriques automatiques

fabrication et équipement de laboratoire de batterie de Li-ion 18650

Organigramme de la pile bouton au lithium-ion et liste des machines

fabrication et équipement de laboratoire de batterie de poche de li-ion

dec 2016 usa client acceptation d'usine de l'empileuse automatique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produits chauds

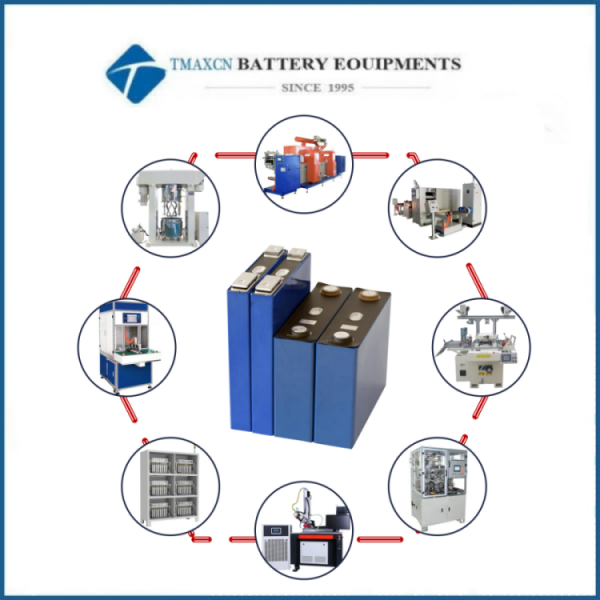

Exploring the Technological Marvels of the Car Battery Pilot Plant

In the ever-evolving landscape of automotive technology, the EV Battery Pilot Plant stands as a beacon of innovation, pushing the boundaries of what's possible in the realm of energy storage. This technological marvel represents a glimpse into the future, where cutting-edge research and development pave the way for the next generation of car batteries. Let's delve into the intricate technicalities that make the Car Battery Pilot Plant a hub of transformative advancements.

1. Advanced Materials Synthesis:

At the heart of the Car battery pilot Line, scientists and engineers engage in the synthesis of advanced materials that form the backbone of revolutionary battery technologies. From high-energy-density cathode materials to efficient anode compositions, every component undergoes meticulous development to enhance energy storage capacity and overall performance.

2. Electrode Manufacturing Precision:

The pilot plant boasts an electrode manufacturing process that redefines precision. Automated systems meticulously deposit active materials onto current collectors, ensuring uniformity and consistency. This precision is not just a matter of manufacturing; it's a fundamental aspect that influences the battery's efficiency, charge-discharge characteristics, and lifespan.

3. Novel Electrolyte Formulation:

In the pursuit of safer and more efficient batteries, the EV Battery Production Plant pioneers novel electrolyte formulations. Advanced electrolytes with enhanced thermal stability and conductivity are meticulously crafted to improve the safety and overall performance of the batteries. These formulations are a testament to the plant's commitment to staying at the forefront of battery technology.

4. Cutting-Edge Manufacturing Processes:

The plant employs cutting-edge manufacturing processes, including roll-to-roll calendering and precision coating techniques. These processes enable the production of thin, flexible batteries suitable for electric vehicles, wearable technology, and other innovative applications. The focus on these advanced manufacturing methods reflects a commitment to adaptability and sustainability.

5. Prototyping and Iterative Design:

One of the distinguishing features of the pilot plant is its emphasis on prototyping and iterative design. Researchers continually refine battery designs based on real-world testing and performance data. This iterative approach accelerates the development of batteries with enhanced energy density, faster charging capabilities, and longer cycle life.

6. In-Situ Characterization Techniques:

The pilot plant employs state-of-the-art in-situ characterization techniques. Researchers can monitor and analyze battery components in real-time during operation. This level of insight allows for a deeper understanding of the electrochemical processes within the battery, leading to more informed design decisions and continuous improvement.

7. Integration of Smart Technologies:

Smart technologies play a pivotal role in the pilot plant, from automated quality control systems to data analytics. These technologies optimize manufacturing processes, enhance efficiency, and provide valuable insights into the performance of each battery prototype. Real-time data analytics contribute to data-driven decision-making, improving overall productivity.

8. Environmental Sustainability Focus:

Environmental sustainability is a guiding principle of the pilot plant. Researchers explore eco-friendly materials, recycling processes, and energy-efficient technologies to minimize the ecological footprint of battery production. This focus aligns with the global commitment to sustainable practices in the automotive and energy sectors.

Conclusion:

The Car Battery Pilot Plant represents a nexus of innovation, where groundbreaking technologies converge to shape the future of energy storage. As it pioneers advanced materials, precise manufacturing processes, and smart technologies, the plant becomes a driving force in the evolution of car batteries. It's not just a facility; it's a testament to the relentless pursuit of technological excellence, propelling us toward a future where energy storage is not just efficient but transformative.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com