catégories de produits

- pilote de batterie / ligne de production

- ensemble de laboratoire de batterie

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Ion Li batterie matériaux

- matériaux actifs cathodiques

- matériaux actifs d'anode

- Customized Battery Electrode

- Matériaux de cellule de pièce

- puce au lithium

- pièces de cellules cylindriques

- collecteurs de courant de batterie

- matériaux conducteurs de batterie

- électrolyte et poche

- Metal Mesh

- liant de batterie

- séparateur et ruban

- film stratifié aluminium

- bande / feuille de nickel

- Battery Tabs

- matériaux de graphène

- Nickel Felt

- Titanium Fiber Felt

- Batterie

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- toutes les machines d'assemblage de batterie

- testeur et analyseur de batterie

- Battery Safety Tester

- Material Characterization Tester

- machine de presse de roulement

- machine de soudage par points en métal

- machine de mélangeur sous vide

- machine à sertir / démonter

- machine de scellage sous vide

- remplissage d'électrolyte

- empileuse / bobineuse

- coupe-électrode / refendeuse

- poche formant la machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Boîte à gants sous vide

- des fours

- Coaters

- PVD Coater

- presse hydraulique

- Large Press Machine

- mélangeur centrifuge planétaire / broyeur

- broyeur à billes

- machine de laboratoire

- Fours sous vide

- chambre d'essai d'humidité de la température

- Hardness Tester

- Spray Dryer

- Cutting Machine

- incubateur

- évaporateurs rotatifs

- Viscometer

- Three Roller Mill

- analyseur de surface

- broyeur de laboratoire

- machine de durcissement UV

- congélateurs ultra-bas

- Water Chiller

- Laser Cleaning Machine

- autre équipement de laboratoire

- Cutting Machine

- mousse d'électrode métallique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- WhatsApp : +86 18659217588

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

2024-05-16

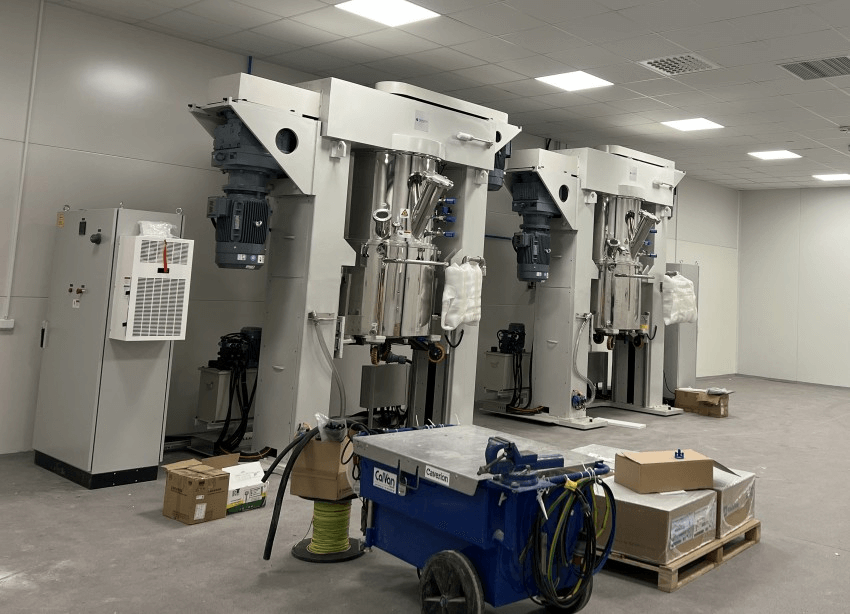

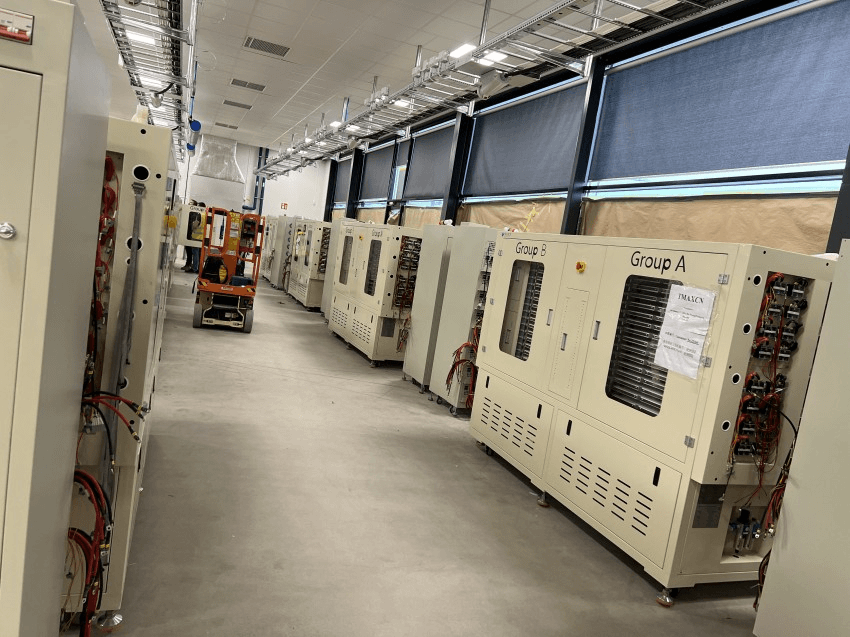

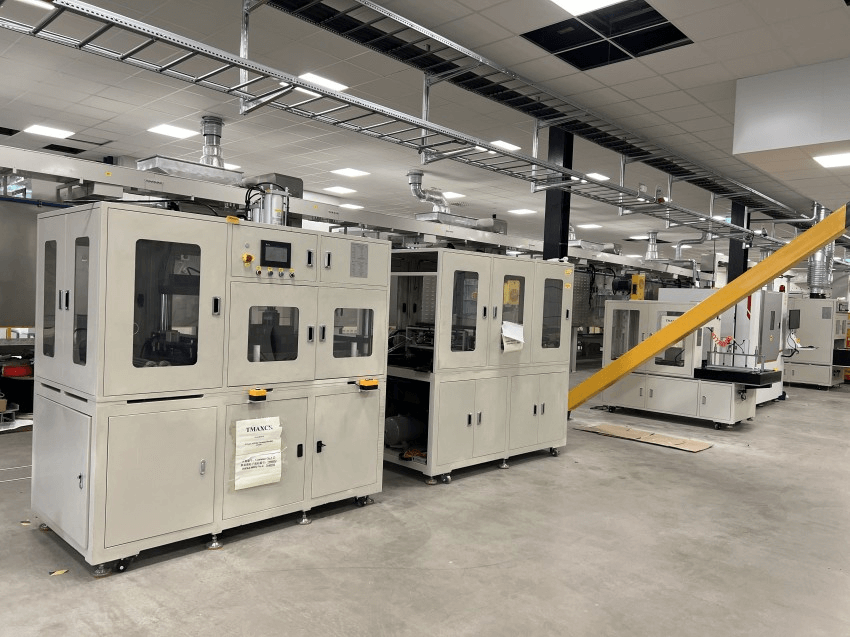

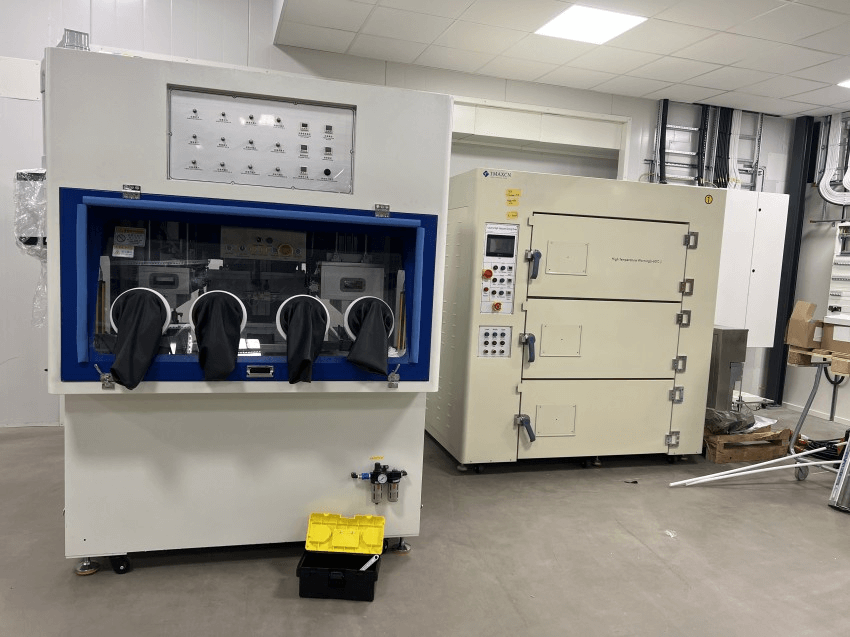

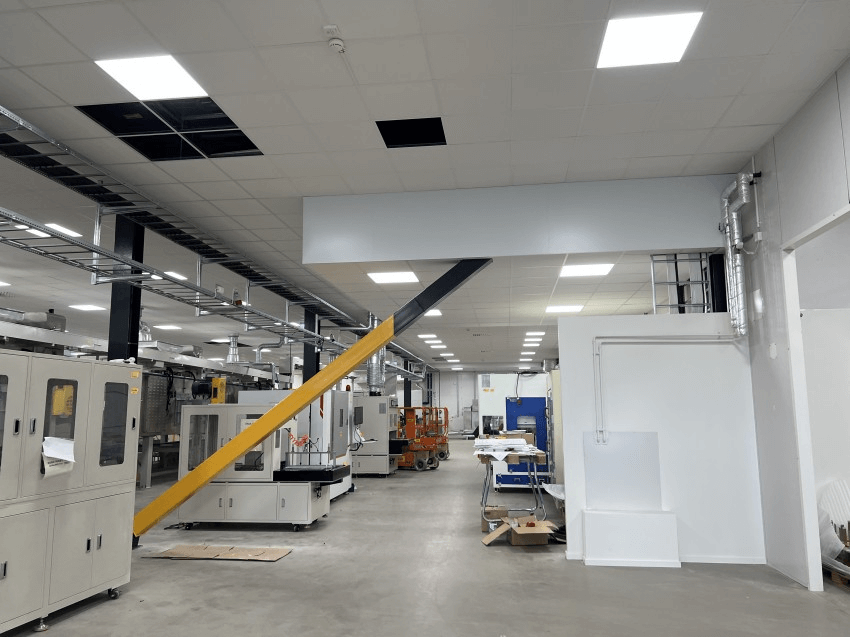

Prismatic Cell Production Line Project in Europe

Description: Xiamen Tmax Battery Equipments Limited has designed and established a prismatic cell production line for European customers. TMAX provides a complete set of prismatic production technology, production line design, raw materials, and various consumables. The entire prismatic cell production line has been installed and debugged by TMAX engineers at the customer's factory, and training has been provided on the use and maintenance of the equipment and all of them reach the acceptance standards.

During the FAT process, the customer conducted a comprehensive inspection and evaluation of our company's product quality, production process, safety and environmental protection. After strict review and testing, the customer expressed satisfaction with our company's products and highly praised our professional ability and service attitude.

The successful installation and inspection of the aluminum shell battery cell production line has not only won our company more market share, but also further enhanced our brand image and technical strength. We will continue to uphold the corporate philosophy of professionalism, innovation, and service, and provide customers with higher quality products and services.

Date: March 2024

Location: Europe

Customer Requirements Form:

Battery Type |

Prismatic Cell |

Design capacity |

100Ah,300Ah |

Material system |

LFP |

Main process |

Stacking |

Production capacity |

2000Pcs/day |

Solution:

(1)Design the whole line production solution of prismatic cell

(2)Provide a complete set of manufacturing equipment from electrode preparation to final cell finishing process

(3)Meet the customer's high capacity, high energy density, and high rate discharge requirements.

Equipment List:

SN. |

Equipment Name |

1 |

|

2 |

Feeding System |

3 |

Slurry Buffer Tank |

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

Ultrasonic Spot Welding Machine (Tab to lid welding) |

11 |

|

12 |

|

13 |

|

14 |

|

15 |

|

16 |

X-ray Tester |

17 |

|

18 |

|

19 |

|

20 |

|

21 |

Laser Welding&Sealing Machine |

22 |

|

23 |

|

24 |

PVC Film Pasting Machine |

25 |

Drying Unit |

26 |

Air Compressor Unit |

27 |

Vacuum Unit |

28 |

Nitrogen Generating Unit |

29 |

|

30 |

Cooler |

31 |

ACIR Tester |

Project Picture:

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com