Site Blog

Blog récent

Ligne de machines de fabrication de production de cellules cylindriques automatiques

fabrication et équipement de laboratoire de batterie de Li-ion 18650

Organigramme de la pile bouton au lithium-ion et liste des machines

fabrication et équipement de laboratoire de batterie de poche de li-ion

dec 2016 usa client acceptation d'usine de l'empileuse automatique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produits chauds

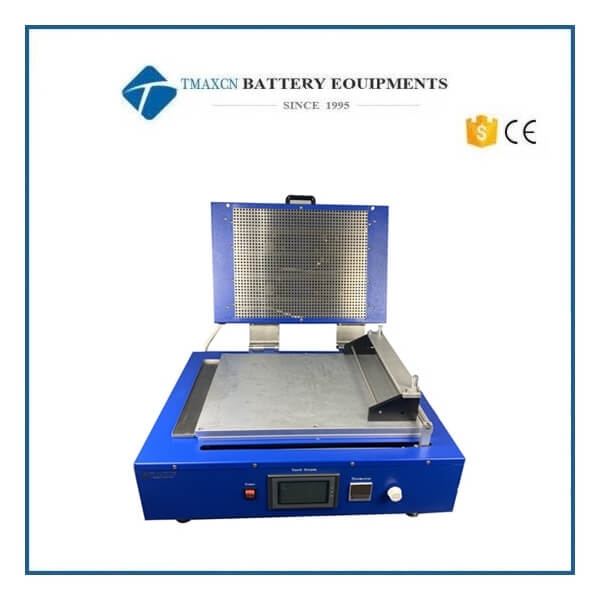

Doctor Blade

In the rapidly evolving field of battery technology, precision and consistency are key to developing high-performance energy storage solutions. One of the most essential tools in this process is the laboratory battery doctor blade. This specialized tool plays a crucial role in the research and development of batteries, particularly in the application of uniform coatings of electrode materials. In this blog post, we will delve into what a laboratory battery doctor blade is, how it works, and its significance in advancing battery technology.

● What is a Laboratory Battery Doctor Blade?

A laboratory battery doctor blade is a precision tool used in the coating process of battery electrodes. In battery research and development, the quality and uniformity of electrode coatings are critical factors that influence the performance, efficiency, and lifespan of the final battery product. The doctor blade is used to apply a controlled, even layer of slurry—a mixture of active materials, binders, and solvents—onto a substrate, which is typically a metal foil like copper or aluminum.

This tool is indispensable in laboratory settings where researchers experiment with different materials and formulations to optimize battery performance. The ability to control the thickness and uniformity of the electrode coatings is essential for understanding how these variables impact the battery's overall characteristics.

● How Does the Laboratory Battery Doctor Blade Work?

The operation of a laboratory battery doctor blade involves several key steps:

1.Preparation of the Slurry: The first step involves preparing the slurry that will be applied to the substrate. This mixture must be homogeneous to ensure consistent coating. The properties of the slurry, such as viscosity and particle size distribution, are critical to achieving a smooth and even coating.

2.Setting the Blade Gap: The gap between the doctor blade and the substrate is carefully adjusted to control the thickness of the coating. This gap can be fine-tuned to achieve the desired thickness, which is usually in the range of a few micrometers. Precise control over this gap is crucial, as even small variations can lead to significant differences in the battery's performance.

3.Coating Process: Once the slurry is ready and the blade gap is set, the coating process begins. The slurry is spread onto the substrate as it moves beneath the doctor blade. The blade evenly distributes the material across the surface, leaving behind a uniform layer that is essential for the battery's electrochemical performance.

4.Drying and Curing: After coating, the electrode must be dried and sometimes cured to remove solvents and solidify the coating. This step is crucial to ensure that the coating adheres properly to the substrate and achieves the desired properties.

● Importance of Uniform Coatings in Battery Performance

The uniformity of the electrode coating directly affects the performance of a battery. Variations in coating thickness can lead to uneven current distribution during charging and discharging, which can reduce the battery's efficiency, capacity, and lifespan. In extreme cases, it can also cause safety issues, such as thermal runaway, which can lead to battery failure.

Moreover, consistent coating thickness is critical for scaling up from laboratory research to commercial production. Inconsistent coatings in the lab can lead to misleading results, making it difficult to translate small-scale findings into practical, large-scale applications.

● Applications in Battery Research

The laboratory battery doctor blade is a versatile tool that supports a wide range of research activities, including:

1.Material Development: Researchers use the doctor blade to test new electrode materials, such as advanced lithium-ion chemistries, solid-state electrolytes, and other emerging technologies. The ability to precisely control coating thickness allows researchers to evaluate the impact of these materials on battery performance.

2.Optimization of Battery Performance: By experimenting with different coating thicknesses and formulations, researchers can optimize the performance of batteries, balancing factors such as energy density, cycle life, and thermal stability.

3.Process Development: The doctor blade is also used to develop and refine the coating processes that will eventually be used in mass production. Understanding how different process parameters affect the final product is essential for scaling up battery manufacturing.

4.Quality Control: In addition to research and development, the laboratory battery doctor blade is also used in quality control processes. Ensuring that each batch of electrodes meets strict specifications is critical for producing reliable and high-performance batteries.

● Conclusion

The laboratory battery doctor blade is a vital tool in the pursuit of advanced battery technologies. Its ability to create uniform, precise coatings makes it indispensable in the research and development of new materials and processes. As the demand for better, more efficient batteries continues to grow, the role of tools like the doctor blade in driving innovation and ensuring quality will only become more significant.

Whether you're developing the next generation of lithium-ion batteries or exploring new chemistries, the laboratory battery doctor blade is a tool that ensures your research is built on a foundation of precision and consistency.

August 20,2024.

Enhancing Battery Research with the Laboratory Battery Doctor Blade

In the rapidly evolving field of battery technology, precision and consistency are key to developing high-performance energy storage solutions. One of the most essential tools in this process is the laboratory battery doctor blade. This specialized tool plays a crucial role in the research and development of batteries, particularly in the application of uniform coatings of electrode materials. In this blog post, we will delve into what a laboratory battery doctor blade is, how it works, and its significance in advancing battery technology.

● What is a Laboratory Battery Doctor Blade?

A laboratory battery doctor blade is a precision tool used in the coating process of battery electrodes. In battery research and development, the quality and uniformity of electrode coatings are critical factors that influence the performance, efficiency, and lifespan of the final battery product. The doctor blade is used to apply a controlled, even layer of slurry—a mixture of active materials, binders, and solvents—onto a substrate, which is typically a metal foil like copper or aluminum.

This tool is indispensable in laboratory settings where researchers experiment with different materials and formulations to optimize battery performance. The ability to control the thickness and uniformity of the electrode coatings is essential for understanding how these variables impact the battery's overall characteristics.

● How Does the Laboratory Battery Doctor Blade Work?

The operation of a laboratory battery doctor blade involves several key steps:

1.Preparation of the Slurry: The first step involves preparing the slurry that will be applied to the substrate. This mixture must be homogeneous to ensure consistent coating. The properties of the slurry, such as viscosity and particle size distribution, are critical to achieving a smooth and even coating.

2.Setting the Blade Gap: The gap between the doctor blade and the substrate is carefully adjusted to control the thickness of the coating. This gap can be fine-tuned to achieve the desired thickness, which is usually in the range of a few micrometers. Precise control over this gap is crucial, as even small variations can lead to significant differences in the battery's performance.

3.Coating Process: Once the slurry is ready and the blade gap is set, the coating process begins. The slurry is spread onto the substrate as it moves beneath the doctor blade. The blade evenly distributes the material across the surface, leaving behind a uniform layer that is essential for the battery's electrochemical performance.

4.Drying and Curing: After coating, the electrode must be dried and sometimes cured to remove solvents and solidify the coating. This step is crucial to ensure that the coating adheres properly to the substrate and achieves the desired properties.

● Importance of Uniform Coatings in Battery Performance

The uniformity of the electrode coating directly affects the performance of a battery. Variations in coating thickness can lead to uneven current distribution during charging and discharging, which can reduce the battery's efficiency, capacity, and lifespan. In extreme cases, it can also cause safety issues, such as thermal runaway, which can lead to battery failure.

Moreover, consistent coating thickness is critical for scaling up from laboratory research to commercial production. Inconsistent coatings in the lab can lead to misleading results, making it difficult to translate small-scale findings into practical, large-scale applications.

● Applications in Battery Research

The laboratory battery doctor blade is a versatile tool that supports a wide range of research activities, including:

1.Material Development: Researchers use the doctor blade to test new electrode materials, such as advanced lithium-ion chemistries, solid-state electrolytes, and other emerging technologies. The ability to precisely control coating thickness allows researchers to evaluate the impact of these materials on battery performance.

2.Optimization of Battery Performance: By experimenting with different coating thicknesses and formulations, researchers can optimize the performance of batteries, balancing factors such as energy density, cycle life, and thermal stability.

3.Process Development: The doctor blade is also used to develop and refine the coating processes that will eventually be used in mass production. Understanding how different process parameters affect the final product is essential for scaling up battery manufacturing.

4.Quality Control: In addition to research and development, the laboratory battery doctor blade is also used in quality control processes. Ensuring that each batch of electrodes meets strict specifications is critical for producing reliable and high-performance batteries.

● Conclusion

The laboratory battery doctor blade is a vital tool in the pursuit of advanced battery technologies. Its ability to create uniform, precise coatings makes it indispensable in the research and development of new materials and processes. As the demand for better, more efficient batteries continues to grow, the role of tools like the doctor blade in driving innovation and ensuring quality will only become more significant.

Whether you're developing the next generation of lithium-ion batteries or exploring new chemistries, the laboratory battery doctor blade is a tool that ensures your research is built on a foundation of precision and consistency.

This draft provides a comprehensive look at the laboratory battery doctor blade, its function, and its importance in battery research and development.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com