Site Blog

Ligne de machines de fabrication de production de cellules cylindriques automatiques

fabrication et équipement de laboratoire de batterie de Li-ion 18650

Organigramme de la pile bouton au lithium-ion et liste des machines

fabrication et équipement de laboratoire de batterie de poche de li-ion

dec 2016 usa client acceptation d'usine de l'empileuse automatique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produits chauds

LiFePO4 Battery Assembly Machine is an automated system designed to assemble LiFePO4 battery cells into a complete battery pack. The machine typically includes various stations and equipment for assembling, testing, and packaging the battery packs.

The LiFePO4 Battery Assembly line may include equipment for the following processes:

1. Battery cell sorting machine : This process involves sorting and grading individual battery cells according to their performance characteristics, such as capacity and internal resistance. Equipment used in this process can include battery testers and analyzers.

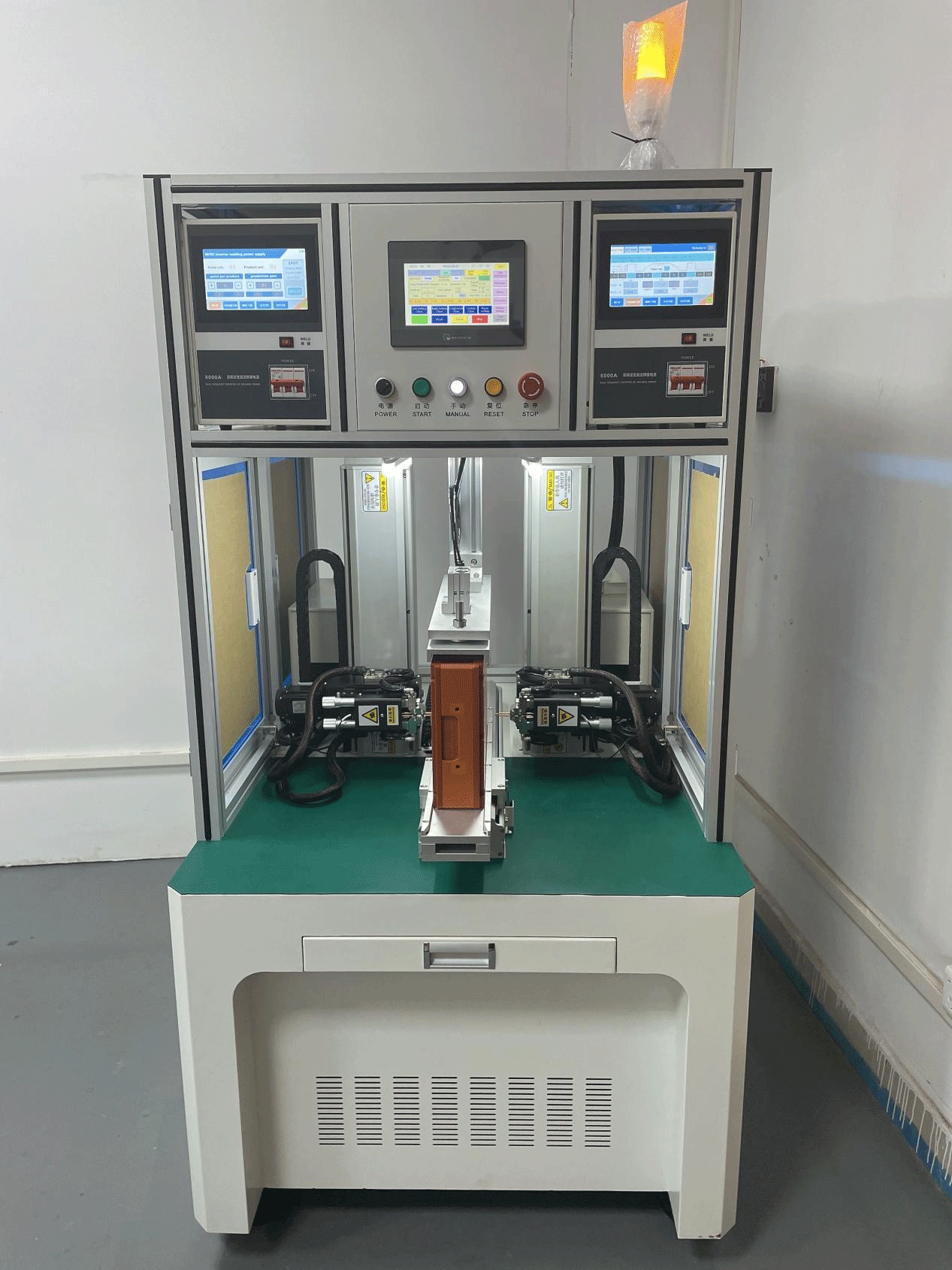

2. Tab welding and cell grouping: Tabs are welded to the positive and negative terminals of the battery cells, allowing them to be connected in series or parallel. Cell grouping involves combining multiple cells into a larger unit. Equipment used in this process can include tab welders and cell grouping machines.

3. Battery cell stacking insulation machine: The battery cells are stacked according to the desired configuration and then insulated to prevent short circuits. Equipment used in this process can include cell stacking and insulation machines.

4. Electrolyte injection and sealing: Electrolyte, a conductive solution that facilitates the movement of ions between the battery's positive and negative electrodes, is injected into the battery cells. The cells are then sealed to prevent leakage. Equipment used in this process can include electrolyte injection and sealing machines.

5. Formation and testing of the battery pack: The battery pack undergoes a process of formation, in which it is charged and discharged multiple times to reach its full capacity. The pack is then tested to ensure that it meets the required specifications, such as voltage and capacity. Equipment used in this process can include battery formation and testing equipment.

6. Battery pack aging machine: The battery pack is aged to simulate its performance over time, as well as its response to various environmental conditions. It is then tested again to ensure that it still meets the required specifications. Equipment used in this process can include aging and testing machines.

7. Battery pack packaging and labeling: The battery pack is packaged according to the customer's specifications and labeled with the necessary information, such as its capacity, voltage, and safety certifications. Equipment used in this process can include packaging and labeling machines.

The machine is typically equipped with a control system to monitor and adjust the production process, ensuring that the battery packs are assembled according to the required specifications and standards. Additionally, the LiFePO4 Battery Assembly Machine may be customized to meet the specific needs of the customer, such as incorporating additional testing or inspection stations.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com