Site Blog

Ligne de machines de fabrication de production de cellules cylindriques automatiques

fabrication et équipement de laboratoire de batterie de Li-ion 18650

Organigramme de la pile bouton au lithium-ion et liste des machines

fabrication et équipement de laboratoire de batterie de poche de li-ion

dec 2016 usa client acceptation d'usine de l'empileuse automatique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produits chauds

Lithium Battery Production Machine: Empowering the Future of Energy Storage

The rise of renewable energy has been transforming the energy sector and it has created a huge demand for high-performance energy storage systems. Lithium batteries are considered the most promising solution to meet this demand. As the popularity of lithium batteries grows, the need for efficient and reliable production machines increases. That's where lithium battery production machines come into play.

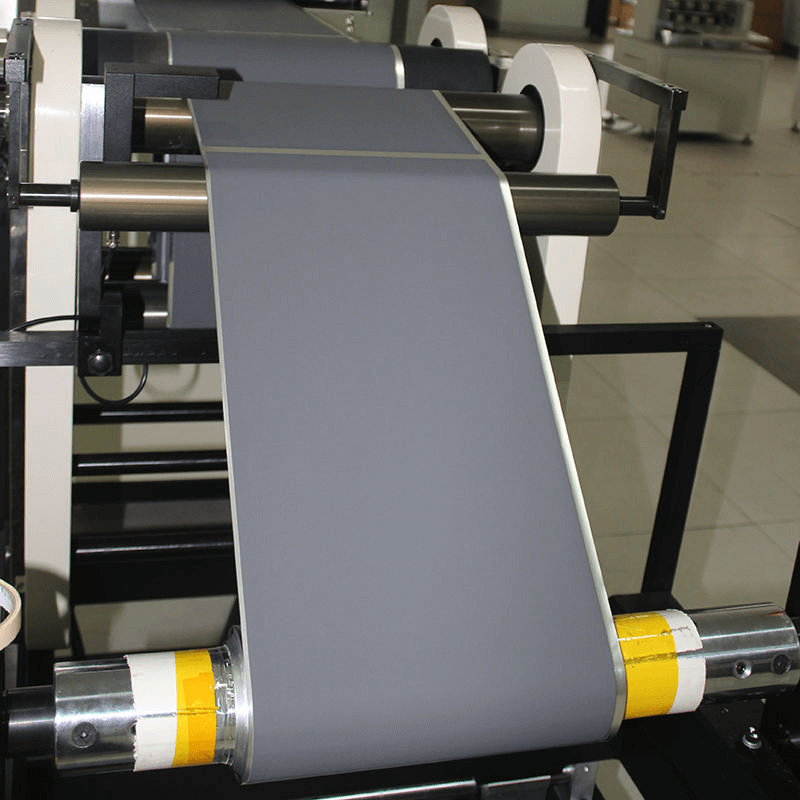

Lithium battery production equipment are designed to manufacture lithium-ion batteries, which are used in electric vehicles, consumer electronics, and renewable energy storage. These machines are capable of producing batteries with different sizes and shapes, including cylindrical, prismatic, and pouch cells. They consist of several components that work together to form a complete battery production line.

The main components of a lithium battery production line include electrode manufacturing machines, cell assembly machines, and battery pack assembly machines. The electrode manufacturing machines are used to produce the anode and cathode materials, while the cell assembly machines are used to assemble the battery cells. Finally, the battery pack assembly machines are used to integrate the cells into a complete battery pack.

Lithium battery production line have a number of advantages. First and foremost, they offer high accuracy and precision during the manufacturing process, ensuring consistent quality of the battery cells. They are also highly efficient, which reduces the production time and the overall cost of manufacturing. Additionally, these machines have a high degree of automation, which minimizes the need for human intervention and reduces the risk of errors.

The lithium battery production machines are also flexible and versatile, as they can be customized to meet the specific requirements of different battery types and sizes. They are also designed to be scalable, so that the production capacity can be easily increased to meet growing demand.

As the demand for lithium batteries continues to increase, the adoption of lithium battery production machines is expected to grow as well. The use of these machines will help to increase the efficiency and quality of the manufacturing process, while reducing the overall cost. This will make lithium batteries more affordable and accessible, and accelerate the transition to a renewable energy future.

In conclusion, lithium battery production plant are an essential part of the lithium battery manufacturing process. They offer a wide range of benefits, including high accuracy, efficiency, and scalability, and are designed to meet the specific requirements of different battery types and sizes. As the demand for lithium batteries grows, the adoption of these machines will become increasingly important in empowering the future of energy storage.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com