Site Blog

Ligne de machines de fabrication de production de cellules cylindriques automatiques

fabrication et équipement de laboratoire de batterie de Li-ion 18650

Organigramme de la pile bouton au lithium-ion et liste des machines

fabrication et équipement de laboratoire de batterie de poche de li-ion

dec 2016 usa client acceptation d'usine de l'empileuse automatique

Contactez-nous

- Si vous avez des questions, veuillez communiquer avec nous, toutes les questions recevront une réponse

- Messagerie : David@tmaxcn.com

- Messagerie : Davidtmaxcn@gmail.com

- Ajouter : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produits chauds

An "battery electrode calender" typically refers to a piece of equipment used in the manufacturing of batteries. The calendering process involves the compression and shaping of electrode materials to improve their properties and enhance the overall performance of the battery. Here is an explanation of the electrode calendering process:

1. Purpose of electrode Calendering Machine

Density Enhancement: The primary objective of electrode calendering is to increase the density of the electrode materials. This is achieved by subjecting the materials to controlled compression, reducing voids and enhancing the packing density.

Uniformity Improvement: Calendering helps in achieving a more uniform thickness and structure of the electrode materials. This uniformity is crucial for maintaining consistent electrochemical performance across the surface of the electrodes.

Surface Smoothing: The calendering process can smooth the surface of electrode materials, reducing irregularities and improving the contact between layers. Improved contact enhances electron and ion flow within the battery, leading to better overall efficiency.

2. Electrode Calendering Process:

Material Preparation: Initially, the electrode materials, such as cathode and anode materials in battery production, are prepared. These materials are often in the form of a slurry.

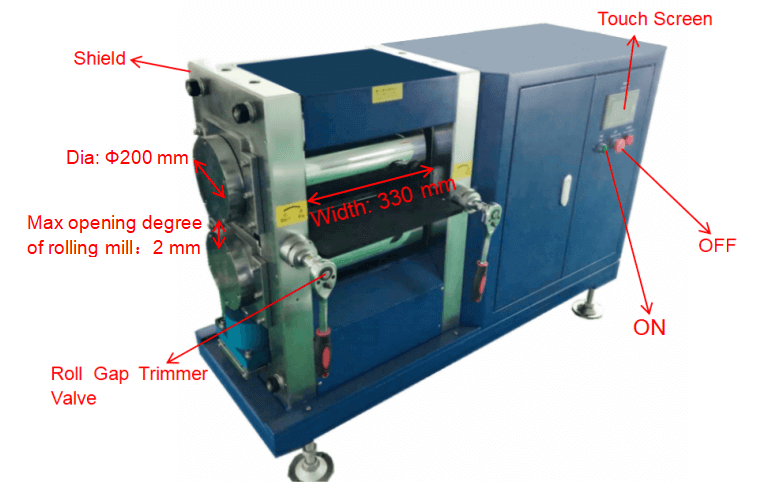

Calendering Machine: The prepared electrode materials are then fed into a calendering machine. This machine typically consists of multiple rollers or a pair of calender rolls.

Rolling and Compression: The material passes through the calender rolls, where controlled pressure is applied. This rolling action compresses the material, reducing its thickness and increasing its density.

Temperature and Humidity Control: In some cases, the calendering process is performed under specific temperature and humidity conditions to optimize the properties of the electrode materials.

3. Importance in Battery Manufacturing:

Enhanced Electrochemical Performance: Electrode calendering is a critical step in battery manufacturing as it directly impacts the electrochemical performance of the battery. The increased density and uniformity of electrodes contribute to improved energy storage and release capabilities.

Consistency Across Cells: Uniformly calendered electrode materials help maintain consistency across battery cells, ensuring that each cell performs similarly. This is essential for the reliability and predictability of the battery pack.

Extended Battery Lifespan: The controlled compression and optimization of electrode materials through calendering contribute to a more robust and durable battery, potentially extending its lifespan.

In conclusion, electrode calendering is a vital process in battery manufacturing, playing a key role in enhancing electrode properties, improving overall battery performance, and contributing to the development of more efficient and reliable energy storage systems.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com